Many students and staff of the ERMP program have been hired into key positions within the local and global pulp industry. Our alumni are making a positive impact on this strategically important industry.

|

Jorge Enrique Rubiano BernaPulp & Paper Development Engineer, KingstonJorge earned his BSc in Chemical Engineering from the Universidad de Valle in his home country of Columbia. He then worked in the pulp and paper industry for three years as a production supervisor of a paper mill (printing and writing grades). In 2011, he began his studies at the prestigious KTH ‐ Royal Institute of Technology, and received a MSc in Chemical Engineering with a minor in Energy and Environment. His thesis investigated pulp morphology and its changes after refining and fractionation processes. Jorge was awarded his PhD in Chemical and Biological Engineering under the supervision of Professors Mark Martinez and James Olson. He also worked as Research Assistant at the Pulp and Paper Centre. Jorge accepted a research position at Dupont, Ontario, in 2019. |

|

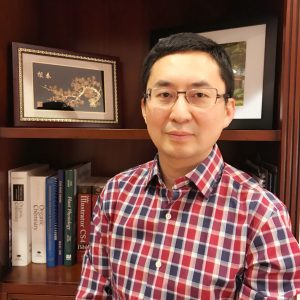

XueFeng (Harry) ChangAssistant Instructor, BCITHarry worked as a Research Scientist during Phase I of the project and as a result, he and Professor Rodger Beatson hold a patent in chemical processing using alkaline peroxide and had five papers published in relation to the project. One of the papers was awarded the Douglas Attach award for best paper presented at the 2011 PAPTAC annual conference. Harry received his MASc in Wood Science from UBC in 2007 and worked as a Research Scientist until the end of 2011. Harry’s role as a Research Associate with Professors Mark Martinez and Rodger Beatson came to a fulfilling close end of June 2017. Effective July 2017, Harry steps into the role of Assistant Instructor at BCIT’s Chemical and Environmental Technology department. |

|

Nici DarychukOperations Specialist, Stock Preparation and Bleaching, Catalyst PaperNici was a Research Assistant and Laboratory Technician from January 2012 to August 2014. She ran and maintained the low consistency refining pilot plant, participated in pilot screening trials, performed lab scale peroxide brightening of mechanical pulps, and performed laboratory testing of pulp and paper properties. This training and experience led her to her current role as Operations Specialist, Stock Preparation and Bleaching at Catalyst Paper, Powell River Division. Nici is still involved in numerous energy reduction initiatives in her current role, mainly around pumping efficiency and low consistency refining, and supervises crews and manages operations in the Stock Preparation and Mechanical Pulp Bleaching departments. |

|

Ali ElahimehrProcess Engineer, Project, Quesnel River Pulp, West FraserAli has been a Process Engineer, Projects, with Quesnel River Pulp, a division of West Fraser Mills since July 2013. He is responsible for evaluating existing processes to reduce cost and improve efficiencies, yields and changeovers; improve process capability and production volume while maintaining and improving quality standards; he develops innovative solutions and best practices to maintain reliable and safe manufacturing systems; and works with equipment designers and manufacturing firms to develop cost effective and working production processes. He also performs research, assesses performance of, and purchases new manufacturing technologies. |

|

Hanya EttefaghResearch Assistant, University of TorontoHanya worked as a Master’s student with the program from 2014-2016 under the supervision of Dr. Farnood at UofT. In that time, she worked on producing multi-ply FBB’s with reject pulp and chemical pretreated pulp in the middle ply, evaluated their mechanical strength and compared them with commercially available FBBs. In the fall of 2016 Hanya was hired on as Research Assistant at UofT. She conducts research on the Zinc-flakes anodes to protect the metal surfaces from corrosion. She is also writing a paper based on her thesis on “Application of low consistency refining on producing multi-ply folding box-boards”. |

|

Francisco FernandezConsultant, Allnorth, VancouverFrancisco was the program manager from May 2013 to July 2014 before accepting a TMP Technical Assistant position with Howe Sound Pulp and Paper Corporation. |

|

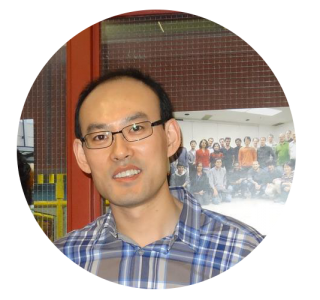

Jiyang GaoProcess Engineer, NeucelJiyang was part of the program for just over five years from late 2007 to early 2013 under the supervision of Mark Martinez and James Olson. At that time he worked on modelling latency removal in mechanical pulping processes, which gave him the necessary experience in pulp and paper and improved his abilities in research and problem solving which lead him to a career with Neucel as a Process Engineer. These days Jiyang spends his time process troubleshooting and optimization, as well as working towards a mill-wide water saving project. |

|

Chunyang HanLecturer, Packaging Engineering, Shenyang Agricultural University, ChinaChunyang worked as a Postdoctoral Research Fellow at the University of Toronto from 2015 to 2016 under the supervision of Ramin Farnood. In that time, he designed the plybond strength fixture of folding box board that can be used on the tensile strength machine to test the plybond strength of FBB. He also developed a new laboratory hand-sheet FBB making procedure, and conducted ANDRITZ trials in 2015 (part of FBB) for the program partners. |

|

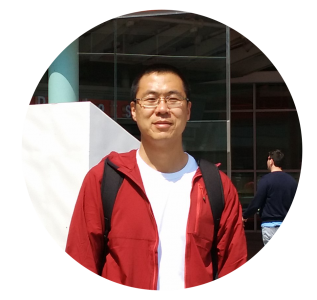

Reza HarirforoushPost-doctoral Fellow, Mechanical Engineering, UBCReza received his BSc and MSc degrees in Mechanical Engineering from Islamic Azad University, Tehran, Iran in 2001 and 2003 respectively. After several years working as a R&D manager, he joined Mechatronic Systems Engineering at Simon Fraser University (SFU) in 2010 and worked as a research and teaching assistant. He received his MASc in 2012, specializing in modal analysis, FEM and modelling. Reza was awarded his PhD in Mechanical Engineering at the University of Victoria under the supervision of Professor Peter Wild. The research involved collaboration with UBC in advanced system integration, sensing and control strategies. He then came to UBC as a post-doctoral fellow. Reza relocated to Michigan, USA in April 2019. |

|

Jens HeymerProduct Engineer, Aikawa Fiber Technologies (AFT)Jens worked as a Postdoctoral Research Fellow under the supervision of James Olson from 2009 to 2011. In that time, he designed and installed the LC refining loop (16” Aikawa refiner), supervised student trials and projects, and conducted industrial trials for the program partners. Jens is now a Product Engineer at Aikawa Fiber Technologies (AFT) and continues to work with the program as a representative of AFT. His main roles fall into four categories including applications, support, product design and optimization. He continues to conduct mill trials and devises solutions for customers; responds to technical inquiries about products; supports the development of the next generation of refining products and improving current products to serve customer needs; and applying value-engineering principles to enhance the design of current FINEBAR products while reducing manufacturing costs and increasing reliability. |

|

Emilia JahangirResearch Assistant — TechnicianEmilia received her B.Sc. in Chemistry from the University of British Columbia. As part of her undergraduate education, Emilia participated in the Research Learning Experience program where she focused on chemical synthesis and purification of modified dipeptides naturally found in ‘death-cap’ mushrooms. She joined the Pulp and Paper Centre in 2013 and was working with the low consistency refining team on various projects. Appointed as a research assistant-technician, Emilia managed and operated the low consistency refining facility at the PPC and contributes to different stages of pulp and paper quality testing. Emilia supervised a team of students, trained team members and researchers on pulp and paper testing, and provided maintenance of laboratory equipment. Mid-August of 2017, Emilia relocated to the US. |

|

Taegeun KangAccount Manager with Saskpower, and Tech Reviewer for Northern Ontario Pulp and Paper millsTaegeun worked with the research program from 2007 to 2009 on novel mechanical pulping, at the time working closely with Quesnel River Pulp. He was then hired as the Energy Manager at Howe Sound Pulp and Paper Corporation. His role involved developing energy saving projects, verifying savings, analyzing billings and promoting employee awareness programs for energy conservation. Taegeun continued to be an active member of the program representing HSPP on the Steering Committee. In March 2016 Taegeun moved into a new role as Senior Technical Specialist, ICF International. His role is to lead the delivery of SaskPower’s Industrial Energy Optimization Program (IEOP) to industrial clients (pulp & paper, oil & gas, food, agricultural & mining) in Saskatchewan and to lead the delivery of Ontario Government’s Northern Industrial Electricity Rate (NIER) program to the forest products clients in Norther Ontario to improve their energy efficiency and sustainability. |

|

Sona KazemiSona joined the ranks of PPC staff to manage the initial proposal of Phase 3 of ERMP research program. Sona’s professional experience covers five years as a research engineer with an R&D enterprise, BC Research Inc., and as the chief technology officer with the clean-tech start-up, Mantra Energy Alternatives. Sona received her PhD from UBC in Chemical Engineering, and BSc and MASc from Sharif University of Technology, Tehran, Iran, also in Chemical Engineering. Sona served as Program Manager from November 2018 until end of March 2019. |

|

Ramin KhoieProcess Systems Solutions Engineer, AutomationXAs part of the AutomationX team, Ramin is responsible for the design and implementation of automation solutions for new and existing process plants with proven results in the Oil & Gas and the Pulp & Paper industries. Ramin completed his master’s program in Applied Sciences under the supervision of Dr. Boris Stoeber in 2016. Within the curriculum of his master’s project, he designed and developed a non-contact magnetic wear sensor to detect erosion inside industrial sized centrifugal pumps. During his time at UBC, he was also elected as the VP Finance for the Mechanical Engineering Graduate Association. |

|

Taraneh KordiChemical Engineering & Applied Science, University of TorontoTaraneh received her B.Sc. in Chemical Engineering from the University of Tehran in Iran in 2015. She worked for her MASc. in Chemical Engineering and Applied Science at the University of Toronto under the supervision of Professor Farnood until September 2018. Her research involved the development of LCR pulp in packaging paper and paperboard. |

|

Antti LuukkonenDirector of the Research & Development Centre, Springfield, OH, AndritzAntti worked on low consistency refining of mechanical pulp from 2007 to 2011 under the supervision of James Olson and Mark Martinez. Working closely with Andritz, he also conducted trials at several local mills. “Without the group I would not be in the position I am today” says Luukkonen. He currently works with Andritz as the Director of the Research & Development Center in Springfield, OH. His advice to current students is to utilize this opportunity to gain as much practical experience as possible since employers are looking for talented, young individuals with multiple skills. |

|

Nick McIntoshPhD Student, Chemical and Biological Engineering, UBCNick worked on compression screw feed optimization and energy savings in high consistency refining, and much of his research focused on liquid uptake capacity. He was with the program from 2014 to 2016 under the supervision of James Olson and Mark Martinez. Nick is now pursuing a PhD and his work will aim to better understand dewatering of pulp. Nick credits the ERMP program for giving him the opportunity to participate in and explore industrial/academic research. Apart from developing a technical skill set, the group promoted and fostered a culture of conducting high-quality, thorough research that is (at least partially) responsible for his decision to remain academically focused and pursue a PhD. |

|

Meaghan MillerProgram ManagerMeaghan received her B.Eng in Mechanical Engineering (Carleton) and an M.Sc. in Sustainable Energy Engineering from the Royal Institute of Technology (KTH) in Stockholm, Sweden, in collaboration with the University of Toronto. In addition to having research experience in fuel cells, she spent two years working in energy consulting, performing detailed energy efficiency studies of commercial buildings and liaising with clients and utilities. Meaghan managed the ERMP research program and was responsible for coordinating the various research projects and working with the programs industrial partners. She also provided oversight for the experimental program, including both mill and pilot scale experimental trials. |

|

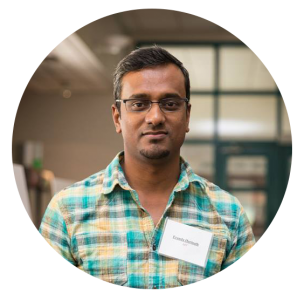

Eranda Puwakkatiya-KankanamgePostdoctoral Associate, MITEranda was with the program from May 2007 to August 2012 under the supervision of Guy A. Dumont working on the refiner control project with partners BC Hydro, Catalyst and Honeywell. Eranda continues to work in academics as a Postdoctoral Associate working on advanced control strategies for continuous pharmaceutical manufacturing processes at the Novartis-Massachusetts Institute of Technology (MIT) Center for Continuous Manufacturing. He credits the program with allowing him the opportunity to gain experience working on multidisciplinary projects, as well as with opportunities to visit other leading research groups in various universities which helped him establish successful research collaborations. |

|

Bahar SoltanmohammadiMASc., Chemical Engineering & Applied Science, University of TorontoBahar received her B.Sc. in Polymer Engineering from University of Tehran, Iran, in July 2016. She researched as an MASc. student in Chemical Engineering and Applied Science at the University of Toronto under the supervision of Professor Farnood. Bahar worked on flexible packaging paper with a main objective of examining the use of LCR mechanical pulp for flexible packaging paper grades. |

|

Yu SunOperations Specialist, Catalyst Paper, Crofton MillYu’s work focused on determining the chemical charges and treatment conditions that are required at various locations of the mechanical pulping process to obtain the desired pulp properties at the lowest energy and cost. Yu was a Postdoctoral Research Fellow with the program from 2014 to 2017 under the supervision of Rodger Beatson at BCIT. In February 2017, Yu accepted a position as Operations Specialist at Catalyst Paper’s Crofton Mill on Vancouver Island. |

|

Hui TianPhD studentHui received her BE and MASc degrees in Control Science and Engineering from Harbin Institute of Technology, Harbin, China, in 2011 and 2013 respectively. Her research interests include robust and model predictive control, estimation and fault detection and diagnosis. Hui did her doctoral research and studies in Chemical and Biological Engineering at UBC under the supervision of Professor Bhushan Gopaluni. She worked on designing a model predictive controller for the refining process in thermo‐mechanical pulping industry. A central goal of her research is to use novel economic and distributed model predictive control strategies to reduce energy consumption in multistage low consistency refining. |

|

Vanessa Van AertResearch TechnicianVanessa graduated from UBC in May 2017 with a Bachelor’s degree in chemical engineering. Following graduation, she spent time travelling through Central America. Vanessa’s previous work experience includes positions with Quesnel River Pulp and Econotech Services. As research technician at UBC, Vanessa analyzed hardwood and softwood kraft pulp following TAPPI, PAPTAC, ISO, and SCAN standard methods. |

|

Miguel VillalbaMiguel graduated from Pennsylvania State University with a B.Sc. degree in Mechanical Engineering in May 2016. He completed his M.A.Sc. in Mechanical Engineering in 2019. His research interests include fluid mechanics and heat transfer applied to industry. Miguel’s project focused on the chemical and enzymatic pretreatment of wood chips for energy savings in mechanical pulping. The project used advanced microscopic and biotechnology techniques to measure the degree of fibre surface area increase and chemical/enzyme penetration under a range of compression and shear conditions. The goal was to optimize the treatment, the design and operation of compression screw-feed systems for energy savings. |

|

Technician Post doctoral fellow, UBC and BCITZhaoyang joined the program in January 2017 and worked with Harry Chang, BCIT, in the area of improving pulp properties using chemical treatment. His research focused on measuring of metal ions and acid groups that affect the utilization of H2O2 treatment of the mechanical pulp for the reduction of refining energy as well as improving pulp properties. His PhD research concentrated on understanding silica and hemicellulose removal from bamboo for the production of kraft pulp or dissolving grade pulp. Zhaoyang received the Second Best Innovation in the 2015 Valmet Tissue Technology competition for his work on silica removal. Zhaoyang was awarded his PhD from the Faculty of Applied Science, UBC, in March 2017. |

|

Bryan BohnBryan received his BSc in Mechanical Engineering from the University of Connecticut in 2010. He recently completed his MASc at the University of British Columbia in February 2021 under the co-supervision of Professors Boris Stoeber and Bhushan Gopaluni. Bryan’s research focused in the development of an inexpensive and adaptable sensor suite to serve as a comprehensive pump performance monitoring system with the goal of minimizing waste energy in pumps and pumping processes. This sensor network would generate continuous efficiency monitoring and allow for accurate maintenance scheduling through predictive pump failure analysis. |